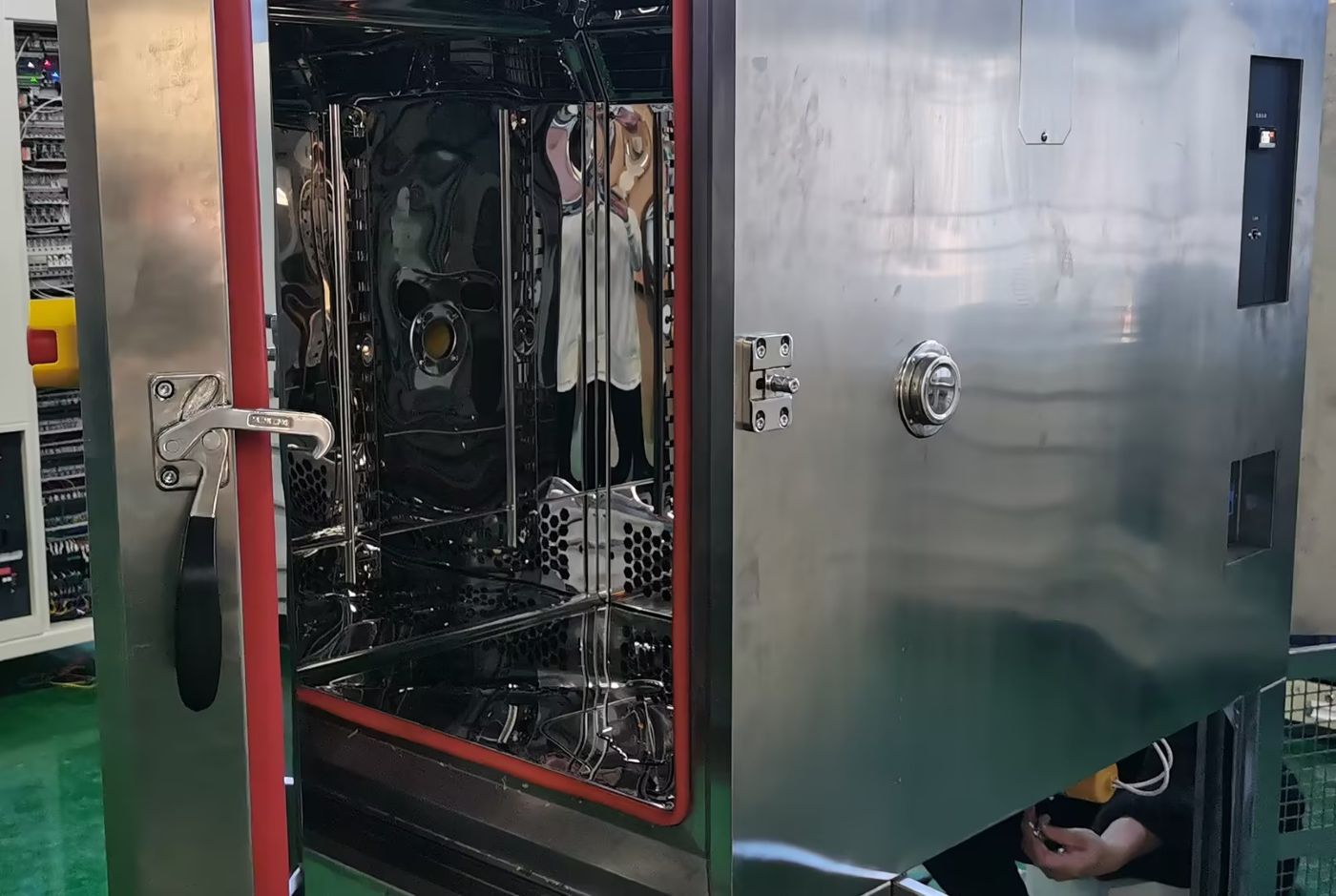

1.Equipment Overview

The Humidity & Temperature Test Chamber, also known as an Environmental Simulation Testing Apparatus, is a precision instrument requiring strict adherence to operational protocols. As a Class II electrical device compliant with IEC 61010-1 safety standards, its reliability (±0.5°C temperature stability), precision (±2% RH humidity accuracy), and operational stability are critical for obtaining ISO/IEC 17025 compliant test results.

2.Pre-Operation Safety Protocols

2.1 Electrical Requirements

- Power supply: 220V AC ±10%, 50/60Hz with independent grounding (ground resistance ≤4Ω)

- Install emergency stop circuit and overcurrent protection (recommended 125% of rated current)

- Implement RCD (Residual Current Device) with tripping current ≤30mA

2.2 Installation Specifications

- Clearance requirements:

Rear: ≥500mm

Lateral: ≥300mm

Vertical: ≥800mm

- Ambient conditions:

Temperature: 15-35°C

Humidity: ≤85% RH (non-condensing)

Atmospheric pressure: 86-106kPa

3.Operational Constraints

3.1 Prohibited Environments

- Explosive atmospheres (ATEX Zone 0/20 prohibited)

- Corrosive environments (HCl concentration >1ppm)

- High particulate areas (PM2.5 >150μg/m³)

- Strong electromagnetic fields (>3V/m at 10kHz-30MHz)

4.Commissioning Procedures

4.1 Pre-Start Checklist

- Verify chamber integrity (structural deformation ≤0.2mm/m)

- Confirm PT100 sensor calibration validity (NIST traceable)

- Check refrigerant levels (R404A ≥85% of nominal charge)

- Validate drainage system slope (≥3° gradient)

5.Operational Guidelines

5.1 Parameter Setting

- Temperature range: -70°C to +150°C (gradient ≤3°C/min)

- Humidity range: 20% RH to 98% RH (dew point monitoring required >85% RH)

- Program steps: ≤120 segments with ramp soak control

5.2 Safety Interlocks

- Door-open shutdown (activation within 0.5s)

- Over-temperature protection (dual redundant sensors)

- Humidity sensor failure detection (auto-dry mode activation)

6.Maintenance Protocol

6.1 Daily Maintenance

- Condenser coil cleaning (compressed air 0.3-0.5MPa)

- Water resistivity check (≥1MΩ·cm)

- Door seal inspection (leak rate ≤0.5% vol/h)

6.2 Periodic Maintenance

- Compressor oil analysis (every 2,000 hours)

- Refrigerant circuit pressure test (annual)

- Calibration cycle:

Temperature: ±0.3°C (annual)

Humidity: ±1.5% RH (biannual)

7.Failure Response Matrix

| Symptom Priority | Priority | Immediate Action | Technical Response |

| Uncontrolled heating | P1 | Activate emergency stop | Check SSR operation (Vf <1.5V) |

| Humidity oscillation | P2 | Initiate auto-dry cycle | Verify dew point sensor calibration |

| Condenser frost | P3 | Reduce humidity setpoint | Check expansion valve (ΔT 5-8°C) |

| Water level alarm | P2 | Refill with DI water | Conduct float switch resistance test |

8.Decommissioning & Disposal

- Refrigerant recovery per EPA 608 regulations

- PCB disposal compliant with RoHS Directive 2011/65/EU

- Steel components recycling (≥95% recovery rate)

9.Compliance Standards

- Safety: UL 61010-2-011, EN 60204-1

- EMC: FCC Part 15 Subpart B, EN 55011

- Performance: ASTM D4332, IEC 60068-3-5