In the ever-evolving construction and stone processing industries, efficiency, precision, and durability are key to achieving superior results. When it comes to surface treatment, whether you're working with stone, concrete, or other hard materials, achieving a consistent, textured finish that ensures durability and aesthetics is crucial. That's where the Multi-Head Bush Hammer Chip-Axe Machine comes into play, revolutionizing the way we approach surface preparation.

The Multi-Head Bush Hammer Chip-Axe Machine is designed to provide exceptional performance by utilizing multiple bush hammer heads that work simultaneously. This powerful, high-efficiency mechanism dramatically reduces processing time while delivering flawless, uniform textures. Whether you're looking to enhance the grip of a floor, improve the appearance of a facade, or add a decorative touch to your stone surfaces, this machine offers unparalleled speed and precision.

With its multi-head design, the machine can cover larger areas in a fraction of the time compared to traditional single-head systems. This means you can achieve more in less time, improving both productivity and profitability.

Built for Durability and Reliability

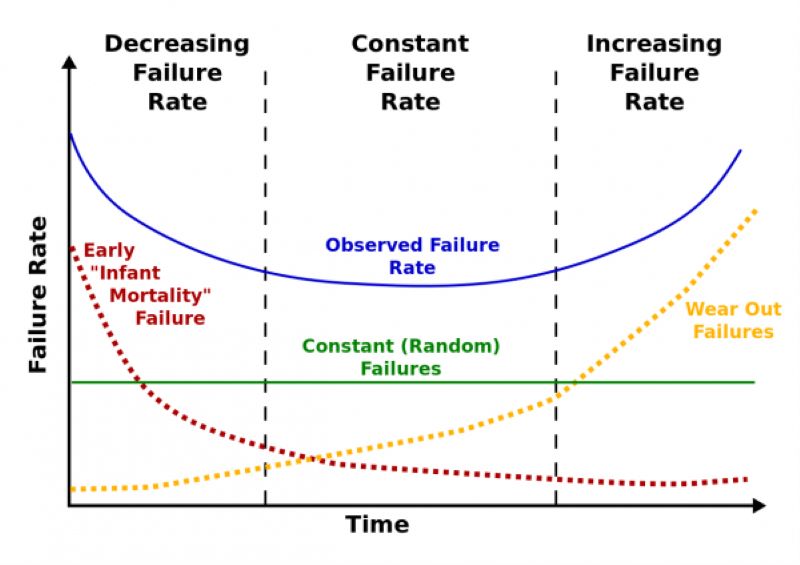

Crafted with heavy-duty, industrial-grade materials, the Multi-Head Bush Hammer Chip-Axe Machine is engineered to withstand the toughest working environments. Whether you're dealing with abrasive materials like concrete or granite, or working in high-demand conditions, this machine is built to endure. Its robust construction ensures long-lasting durability, requiring minimal maintenance, and providing excellent return on investment.

The machine’s advanced control system allows for smooth operation and precise adjustments, ensuring the surface finish is exactly as required. With customizable settings for intensity and depth, you can tailor each processing session to your specific material and project needs.

Versatile and Powerful Performance

From creating non-slip surfaces for walkways to preparing textured finishes for walls and decorative stone, the Multi-Head Bush Hammer Chip-Axe Machine excels across a wide range of applications. Its ability to create high-impact textures is not only crucial for aesthetic appeal but also for enhancing safety in commercial and residential spaces. Whether it’s a high-traffic area or a delicate stone façade, this machine ensures each surface is treated with care and precision.

Moreover, the flexible adjustment mechanism allows operators to control the texture's depth, from a light, sandblasted finish to a more rugged, heavily-textured surface. The versatility of this machine makes it ideal for both small-scale projects and large, high-volume production environments.

Efficient and Cost-Effective Solution

In today’s competitive market, reducing operational costs while maximizing productivity is essential. The SMT Multi-Head Bush Hammer Chip-Axe Machine offers an efficient and cost-effective solution to meet these demands. By speeding up the surface preparation process and minimizing the need for manual labor, businesses can increase output, reduce costs, and ultimately improve their bottom line.