Stone polishing machine is a stone surface, edge grinding, polishing and other different processes of multi-functional machine, understand the types of stone polishing machine, working principle, use of skills, can help you achieve the desired processing results.

First, the types of stone polishing machine

1. manual stone polishing machine: suitable for dealing with small areas of stone, easy to operate, suitable for a variety of thicknesses of plates and tombstones and other flat grinding.

2. bridge type stone polishing machine: used for large area stone surface grinding, high degree of automation, efficiency is also very good, common in stone processing plant.

3. multi-head continuous polishing machine: this is a special equipment in the production line, can smoothly complete the whole process from rough grinding to fine polishing, suitable for high-volume processing.

4. portable stone polishing machine: small size, easy to carry, suitable for the site of a small range of polishing, commonly used in stone care and maintenance.

Second, the working principle of stone polishing machine

Stone polisher is through the following steps to achieve polishing:

1. coarse grinding stage: the use of diamond grinding disc to remove the uneven part of the stone surface.

2. fine grinding stage: gradually switch to finer abrasives for fine grinding.

3. polishing stage: final polishing with resin discs or felt wheels with polishing compounds.

4. crystallisation (optional): increase the luster and hardness of the stone surface through chemical reaction.

Third, the stone polishing machine purchase guide

In the purchase of stone polishing machine, should consider these factors:

1. processing needs: according to the area of the stone to be processed and frequency to choose the right equipment.

2. power size: generally between 1.5-5HP, the higher the power, the higher the efficiency.

3. Speed adjustment: adjustable speed models can adapt to different polishing stages.

4. weight and portability: if it is for on-site use, you have to consider the movement of the equipment.

5. accessories supply: understand the grinding discs and other wearing parts of the replacement cost and access to difficulty.

Fourth, the use of stone polishing machine skills

Preparation

- Clean the surface of the stone, remove impurities.

- According to the type of stone to choose the appropriate grinding disc and polishing agent.

- Check whether the various parts of the equipment is installed firmly.

Operating points

- Replace the grinding discs in the order from coarse to fine.

- Maintain an even speed to avoid localised over-polishing.

- Regularly check the wear of the discs and replace them in time.

- Use the right amount of water to cool down and prevent the stone from cracking.

Safety Precautions

- Wear protective glasses and dust mask.

- Ensure that the working area is well ventilated.

- Keep the equipment in a stable position when running.

- Regularly check the insulation of the wire.

Fifth, stone polishing machine maintenance

Clean the equipment after each use, especially the heat sink. Regularly check the wear and tear of carbon brushes and replace them in time. Bearing parts should be regularly refuelled. Store the equipment in a dry place to avoid dampness of the motor.

When not in use for a long time, disconnect the power supply and remove the grinding disc.

The use and maintenance of stone polishing machine

48SETS XP600 ECO SOLVENT PRINTER LOADING CONTAINER

Do you know what loading means in foreign trade? Successful cabinet packing plays an important role in foreign trade business and is an important step to complete the whole business process. So how do we pack cabinets?

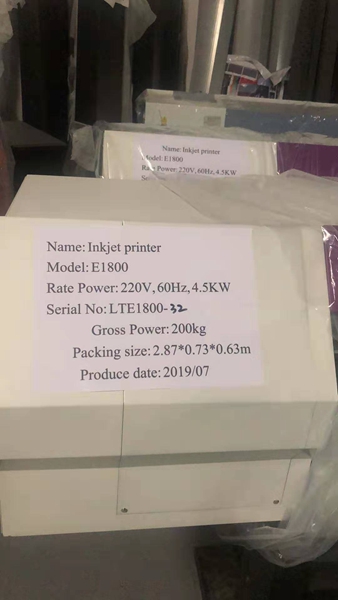

On July 15, 2019, we installed a 40HQ container in Guangzhou warehouse, mainly with 48 set recently popular 1.8m, single head Eco solvent printer with XP600 printing head.

First of all, sinodigitech has designated personnel to do a good job of loading process planning, according to the needs of planning.

Before loading, we need to confirm that the goods to be loaded are correct before we can start formal loading. So when we arrive at the warehouse, we need to confirm with the warehouse manager that the goods are in good quantity and can be loaded.

Then, the division of labor and cooperation began, recorder (2 people),container personnel (6 people), forklift (1 vehicle), recorder were assigned to guide the loading of the container, in the car to guide the next loading of the forklift, another guide forklift loading, in the process of loading, recorded the photos and videos of the loading of the container. As shown in the figure:

Next, after checking all the goods that need to be loaded into the container, put the relevant documents into the container, block the container, confirm the quantity and type of goods with the driver, take photos and record the container number, license plate number (front and back two), key number and record the time of completion, the time of departure of the car, driver's telephone and other relevant information.

Let’s browse the following video to know more about loading process.

Hot Melt Butt Welding Machine Enhancing Efficiency and Precision in Pipe Joining

In the realm of pipe joining technologies, the hot melt butt welding machine has emerged as a game-changer. Designed to bring unmatched efficiency and precision to the process, this advanced welding machine has quickly gained popularity in various industries.

The ppr pipe hot melt butt welding machine utilizes a specialized technique to join thermoplastic pipes with exceptional strength and integrity. It involves melting the ends of the pipes and then bringing them together, creating a seamless and robust fusion. This method ensures leak-free connections, making it ideal for applications in plumbing, irrigation, gas distribution, and more.

With its automatic operation and precise temperature control, the machine eliminates human error and ensures consistent welds. The machine's intuitive interface allows users to easily set the desired parameters, such as fusion time and temperature, guaranteeing optimal results every time.

One of the key advantages of the plastic pipe butt welding machine is its versatility. It can handle a wide range of pipe materials, including polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Whether for large-scale infrastructure projects or small-scale plumbing repairs, this welding machine offers a reliable and efficient solution.

Furthermore, the Butt Welding Machine for PVDF Pipe boasts a sturdy construction and a durable heating element, ensuring a long service life. Regular maintenance and calibration help to optimize its performance and prolong its lifespan, making it a cost-effective investment for businesses.

To ensure customer satisfaction, reputable manufacturers provide comprehensive technical support and training. This ensures that users can operate the machine effectively, maintain it correctly, and troubleshoot any potential issues. Additionally, these manufacturers offer a wide range of accessories and spare parts, ensuring a seamless experience for their customers.

In conclusion, the hot melt butt welding machine is revolutionizing the pipe joining industry with its exceptional efficiency, precision, and reliability. With its automatic operation, precise temperature control, and versatility, this welding machine is a valuable tool for professionals in various sectors. By investing in this advanced technology, businesses can enhance their productivity, minimize, and achieve reliable and durable pipe connections.

The Versatility and Efficiency of Manual Plastic Pipe Butt Welders

In the field of plastic pipe welding, manual butt welders play a crucial role in creating strong and reliable joints. One such example is the SD200(4R) manual butt welder, a versatile and efficient tool that has recently made its way to Cambodia. This cutting-edge welding machine offers exceptional performance and precise control, making it a valuable asset for various industries and applications.

The SD200(4R) manual butt welding machine is designed to meet the demands of pipe welding projects. With its robust construction and high-quality components, it ensures consistent and reliable performance. Its user-friendly interface allows operators to easily control and adjust key parameters, ensuring precise and accurate welding results.

The versatility of the plastic pipe butt welder enables it to be suitable for a wide range of plastic pipe materials, including HDPE, PP, and PPR pipes. This makes it an ideal choice for diverse applications such as water supply systems, gas pipelines, irrigation networks, and industrial piping projects. The welder's ability to handle pipe sizes ranging from XXmm to XXmm further enhances its adaptability.

The manual butt welder's semi-automatic operation allows for greater efficiency and productivity. It features a quick-heating system that significantly reduces welding time, enabling operators to complete projects in a timely manner. With precise temperature and pressure control, the welder ensures consistent joint quality, minimizing the need for rework and enhancing overall productivity.

The Plastic Pipe Butt Fusion Welding Machine is designed for long-term use and requires minimal maintenance. Its sturdy construction and durable components contribute to its reliability, ensuring that it can withstand the demands of challenging work environments. Additionally, the machine's compact size and portability make it convenient to transport to different job sites.

The arrival of the HDPE Pipe Welding Machine in Cambodia marks a significant advancement in plastic pipe welding technology. Its exceptional performance, versatility, and efficiency make it an invaluable tool for various industries and applications. With its user-friendly operation, precise control, and durable design, the manual butt welder is set to revolutionize the welding process, offering reliable and long-lasting joints for plastic pipe systems in Cambodia and beyond.

For more information or to inquire about the SD200(4R) manual butt welder, please contact our team at HunterLee@ahhaida.com.

|

|

Six Major Reasons for the Corrosion of Industrial Chillers

With the continuous advancement of technology, industrial chillers have found increasingly widespread applications in various industrial fields. They play a crucial role in ensuring the efficient operation of industrial production and enhancing product quality. However, as mechanical equipment, industrial chillers are inevitably prone to certain issues during long - term operation. One of the common problems is equipment corrosion. To effectively prevent the corrosion of industrial chillers and extend their service life, Hengde Company elaborates on the six major common causes of chiller corrosion and provides corresponding preventive measures.

1. Corrosion Issues Caused by Unreasonable Engineering Construction, Design, and Installation

Some factories, especially when selling ordinary industrial chillers, cut corners to reduce costs and neglect essential anti - corrosion and anti - rust treatments. Once customers expose the chiller to the outdoor environment for an extended period, the equipment shell is highly susceptible to corrosion. This corrosion risk resulting from the neglect of anti - corrosion measures in the early construction and installation stages can severely affect the normal operation and service life of the chiller.

Preventive Measures: When purchasing equipment, choose suppliers with good reputations and quality guarantees to ensure that the chiller has undergone comprehensive anti - corrosion and anti - rust treatments before leaving the factory, such as spraying high - quality anti - corrosion paint and using corrosion - resistant materials for the shell. Before installation, assess the installation environment and avoid placing the equipment in humid, dusty, or corrosive gas environments. If outdoor installation is unavoidable, build a protective shed to shield the equipment.

2. System Pipeline Corrosion Caused by Incorrect Installation or Abnormal Operation of the Water Processor

In water cooled chillers, the cooling water pipeline is a key passage for cooling water circulation. The quality of the water directly determines whether scale and rust will form in the system pipelines. If the water processor is installed improperly or operates abnormally, it cannot effectively treat the water quality, thereby triggering pipeline rust. This not only reduces the heat exchange efficiency of the chiller but may also lead to pipeline blockages, affecting the stable operation of the entire system.

Preventive Measures: Before installing the water processor, strictly follow the product manual for correct installation and conduct debugging after installation to ensure its normal operation. Regularly maintain and service the water processor, checking whether all its functions, such as filtration, sterilization, and descaling, are normal. Meanwhile, regularly test the cooling water quality and adjust the operating parameters of the water processor or replace consumables like filter elements in a timely manner according to the water quality conditions.

3. Insufficient Filtration of Fine Impurities by Y - type Filters

Currently, the commonly used dirt removers in industrial chillers are mostly Y - type filters. They have the advantages of easy installation and convenient dirt cleaning and can conduct preliminary rough filtration of mechanical impurities, iron filings, and sand grains. However, their filtration effect on tiny impurities is unsatisfactory. As the unit operates for a long time, the condenser is extremely likely to accumulate dirt, sludge, and other impurities. These deposits not only reduce the heat transfer performance of the condenser but may also accelerate the equipment's corrosion process due to the formation of a local corrosion environment.

Preventive Measures: Based on the Y - type filter, add a precision filter to conduct more refined filtration of tiny impurities. Regularly clean and maintain the Y - type filter and the precision filter, and promptly remove the impurities inside the filters. At the same time, regularly clean the condenser. Chemical cleaning or physical cleaning methods can be used to remove the dirt and deposits inside the condenser and maintain its good heat transfer performance.

4. Absence of a Quick Drain Valve in the Chilled Water System

The quick drain valve plays an important role in draining in the chiller or chilled water system. It has a simple structure, good sealing performance, small size, and light weight, and is especially suitable for regular draining of the system. It also has the advantages of corrosion resistance, impact resistance, and long service life. However, currently, many industrial chiller end plates in enterprises do not have a quick drain valve installed, which is likely to cause system pipeline corrosion. During the daily operation of the chiller, it is recommended to open and close the drain valve three times a week to ensure smooth system drainage and maintain the good operation of the system.

Preventive Measures: For chilled water systems that have not installed a quick drain valve, install a quick drain valve that meets the system requirements as soon as possible. In daily use, strictly follow the recommended operation frequency to open and close the drain valve to ensure that impurities and dirt in the system are discharged in a timely manner. At the same time, regularly check the sealing performance and working status of the drain valve and replace it promptly if it is damaged.

5. Absence of a Water Meter in the Cooling System Makeup Water Pipeline

In the water quality treatment process of the cooling system, chemicals and bactericides are usually used to kill fungi, microorganisms, and remove various dirt inside the pipeline. The dosage of the chemicals needs to be accurately adjusted according to the makeup water volume and the system water volume. If there is no water meter installed in the cooling system makeup water pipeline, it is impossible to accurately measure the makeup water volume, resulting in inaccurate chemical dosing. Excessive dosing may cause chemical corrosion of the pipeline, while insufficient dosing cannot effectively inhibit the growth of microorganisms and the formation of dirt, also triggering system pipeline corrosion problems.

Preventive Measures: Install a water meter with appropriate accuracy in the cooling system makeup water pipeline to accurately measure the makeup water volume. According to the system water volume and makeup water volume, accurately calculate the dosage of the chemicals according to the chemical usage instructions. At the same time, regularly test the water quality of the cooling system and adjust the dosage and type of the chemicals in a timely manner according to the test results to ensure that the water quality is in a good state.

6. Corrosion of the Equipment Surface by Acidic and Alkaline Gases in the Environment

During factory production, some special gases, such as acidic and alkaline gases, are inevitably generated. These gases flowing in the environment can cause erosion damage to the equipment surface. Therefore, when selecting a chiller in an environment with such special gases, it is necessary to explain the situation in detail to professionals in advance so that explosion - proof and corrosion - resistant materials are preferentially selected for the production of the electrical control box or evaporator pipeline. This can effectively prevent the equipment from being corroded and damaged by acidic and alkaline gases during the later operation.

Preventive Measures: During the equipment selection stage, fully consider the gas components and concentrations in the working environment and choose chillers with corresponding protection levels and corrosion - resistant properties. For installed equipment, gas purification devices can be set up around the equipment to reduce the concentration of acidic and alkaline gases in the environment. Regularly inspect and maintain the equipment surface. If there are signs of corrosion, promptly carry out repair and protection treatments, such as repainting anti - corrosion paint.

With the rapid development of industry and the continuous emergence of new materials and new processes, the application scenarios of industrial chillers are becoming increasingly diverse, which increases the risk of equipment corrosion. Here, Hengde earnestly reminds industry friends that for industrial chiller equipment, real - time maintenance and customized servicing remain the keys to reducing corrosion and extending the service life. Only through scientific and reasonable maintenance measures can industrial chillers operate continuously and stably in complex industrial environments and provide reliable support for industrial production. When you plan to buy an industrial chiller, Hengde Company is your reliable choice. We offer high - quality products and professional services to meet all your needs.

Choose Hengde, Choose Perfect Industrial Chiller!

Applications of Color Sorters in Different Grain Types

In today´s agricultural and food processing industries, maintaining product quality and safety is non-negotiable. At HTsorter, we specialize in advanced color sorting solutions that cater to diverse grain types, from staple crops like corn and soybeans to niche grains such as millet and barley. This blog explores how our color sorter for corn and soybeans, color sorter use in millet and barley processing, and multi-grain color sorter uses are transforming food production worldwide.

1. Optimizing Corn and Soybean Processing with HTsorter´s Technology

The color sorter for corn and soybeans is a cornerstone of modern grain processing. Corn and soybeans are prone to contamination from mold, stones, or damaged kernels, which can compromise both safety and market value. HTsorter´s systems tackle these challenges through:

High-Resolution Imaging: Utilizing 50+ megapixel CCD cameras to detect subtle defects like mold spots or discoloration in soybeans and corn kernels.

AI-Powered Sorting: Machine learning algorithms distinguish healthy grains from impurities (e.g., broken corn or shriveled soybeans) with 99.9% accuracy.

Scalable Throughput: Systems process 0.6–10 tons per hour, ideal for small farms and large industrial plants alike.

For example, our color sorter for corn and soybeans removes foreign materials like glass or metal fragments, ensuring compliance with food-grade standards while maximizing yield.

2. Enhancing Millet and Barley Quality Through Precision Sorting

Millet and barley, though smaller in size, demand equally rigorous quality control. The color sorter use in millet and barley processing addresses unique challenges such as:

Mold and Fungus Detection: Infrared sensors identify moisture-damaged grains invisible to the naked eye.

Size and Shape Sorting: Separate undersized millet grains or oversized barley kernels to maintain uniformity.

Dust Resilience: HTsorter´s enclosed designs prevent dust interference, critical for fine grains like millet.

Our systems also excel in removing husks, stems, and other organic debris, making them indispensable for producing premium-grade millet flour or malting barley.

3. Versatility of Multi-Grain Color Sorter Uses

For facilities handling multiple grain types, HTsorter´s multi-grain color sorter uses offer unparalleled flexibility:

Adaptive Settings: Switch between corn, soybeans, millet, and barley with pre-programmed sorting profiles.

Cost Efficiency: One machine replaces multiple single-purpose systems, reducing capital and maintenance costs.

Broad Compatibility: Process hybrid batches (e.g., mixed feed grains) while maintaining 99%+ purity rates.

This versatility is powered by modular components, such as adjustable chutes and customizable airflow, ensuring seamless integration into existing production lines.

4. Why HTsorter Stands Out

Global Certifications: CE, ISO9001, and SGS certifications guarantee reliability and safety.

Smart Maintenance: Self-diagnostic tools and remote monitoring minimize downtime.

Sustainable Design: Energy-efficient motors and recyclable materials align with eco-friendly practices.

From bulk corn processing to niche barley refinement, HTsorter´s color sorter for corn and soybeans, color sorter use in millet and barley processing, and multi-grain color sorter uses redefine efficiency in the agricultural sector. By combining cutting-edge optics, AI, and adaptable engineering, we empower producers to meet stringent quality standards while boosting profitability.

Unlocking Efficiency and Sustainability The Transformative Role of Color Sorting Machines in Plastic Recycling

In an era where sustainability and resource efficiency are no longer optional but imperative, industries and recycling facilities are turning to advanced technologies to streamline operations and maximize material recovery. Among these technologies, color sorting machines have emerged as a game-changer, particularly in the processing of plastics such as PET, HDPE, and PVC. These systems not only enhance the quality of recycled materials but also contribute to a circular economy by ensuring that plastics are reused effectively.

The Critical Need for Precision in PET Bottle Recycling

PET (polyethylene terephthalate) is one of the most widely recycled plastics globally, commonly used in beverage bottles, food containers, and textiles. However, recycling PET poses a unique challenge: mixed-color bottles can degrade the value of recycled material. For instance, a single green or blue bottle in a batch of clear PET can compromise the clarity and purity required for food-grade applications. This is where PET bottle sorting machines for recycling step in.

HTsorter’s advanced color sorting systems utilize hyperspectral imaging and AI-driven algorithms to detect and separate PET bottles by color with pinpoint accuracy. By removing contaminants and color inconsistencies early in the recycling process, these machines ensure that the output material meets stringent quality standards. The result is higher-value recycled PET (rPET) that can be safely repurposed for new bottles, packaging, or even clothing fibers. For recycling plants, this translates to increased profitability and reduced waste, while manufacturers gain access to premium-grade recycled materials to meet consumer demand for sustainable products.

Elevating Industrial Efficiency with HDPE Plastic Sorting

HDPE (high-density polyethylene) is another cornerstone of modern manufacturing, found in products ranging from milk jugs and shampoo bottles to industrial pipes. Unlike PET, HDPE is often used in opaque or heavily pigmented forms, making manual sorting impractical for large-scale operations. The HDPE plastic sorting machine for industrial processing addresses this gap by automating the separation of HDPE by color, density, and even polymer type.

In industrial settings, mixed HDPE waste can include materials with varying melting points, additives, or chemical compositions. HTsorter’s technology employs near-infrared (NIR) sensors combined with high-speed air ejectors to categorize HDPE flakes or pellets rapidly. This precision minimizes cross-contamination, ensuring that recycled HDPE retains its structural integrity and performance characteristics. For industries reliant on HDPE, such as automotive or construction, consistent material quality is critical. By integrating color sorting systems, manufacturers can reduce reliance on virgin plastics, lower production costs, and align with global sustainability targets.

Tackling Complexity in PVC Waste Management

PVC (polyvinyl chloride) presents a unique set of challenges in the recycling landscape. While durable and versatile, PVC often contains additives like plasticizers or stabilizers that can be hazardous if not properly managed. Additionally, PVC waste streams may include materials in a spectrum of colors, from white pipes to brightly colored cables. The PVC color sorting system for plastic waste offers a solution by combining color detection with material analysis to segregate PVC by both hue and chemical composition.

HTsorter’s PVC sorting systems are designed to handle the complexities of mixed plastic waste. By identifying and separating PVC based on color and chemical signatures, these machines prevent incompatible materials from entering the recycling stream. This is particularly vital for applications where recycled PVC is repurposed into new products like flooring, roofing membranes, or traffic cones. Clean, well-sorted PVC not only reduces environmental risks but also enhances the safety and longevity of end products.

A Sustainable Future Powered by Innovation

The applications of color sorting machines extend far beyond mere material separation. For PET, HDPE, and PVC recycling, these systems are catalysts for efficiency, quality, and environmental stewardship. By automating processes that were once labor-intensive and error-prone, HTsorter’s technologies empower industries to meet the dual demands of economic viability and ecological responsibility.

As regulations tighten and consumer preferences shift toward sustainable practices, investing in advanced sorting solutions is no longer a luxury—it’s a necessity. Whether it’s enabling food-safe rPET production, optimizing HDPE reuse in manufacturing, or safely managing PVC waste, color sorting machines are paving the way for a future where plastics are not discarded but reintegrated into the value chain.

At HTsorter, we’re committed to driving this transformation. By combining cutting-edge technology with a deep understanding of material science, we help businesses turn waste into opportunity—one sorted pellet at a time.

Unveiling High-Tech Color Sorters How Optical Sorting Enhances Production Efficiency

Ever wonder how your recycled plastic bottle gets turned into a new product? Or why the nuts you buy never have weird bits in them? The secret lies in best high tech color sorters—machines that work like super-powered eyes to spot and remove junk. At HTsorter, a leading name among optical sorting machine manufacturers, we build these smart systems to help factories save time, money, and the planet. Let’s break down how it all works—no jargon, we promise!

1. “Seeing”the Invisible: The Magic of AI Plastic Sorting Technology

Imagine trying to sort a mountain of mixed plastic scraps by hand. Sounds impossible, right? That’s where AI plastic sorting technology comes in. Our machines use smart cameras and sensors to scan every piece of material flying down a conveyor belt. Think of it like a TikTok filter, but instead of adding bunny ears, it spots things like:

A green PET bottle mixed with white HDPE lids

A tiny metal fragment hiding in a pile of plastic flakes

Even weirdly colored grains or nuts that don’t belong

The AI learns from thousands of examples, so it gets better over time. One recycling plant in Thailand saw a 25% jump in clean plastic output after switching to our system. Less trash goes to landfills, more gets reused—win-win!

2. Why Factories Love the Best High Tech Color Sorters

Old-school sorting machines are slow and miss a lot. But the best high tech color sorters (like ours!) fix three big headaches:

Speed: They can check 10,000+ items per minute—faster than a caffeine-powered worker!

Accuracy: Our machines spot flaws as small as a sesame seed. No more recalls because of a rusty screw in your cereal box.

Flexibility: Switch from sorting rice to recycling e-waste with a few clicks. No need to buy new gear.

Take a coffee factory in Brazil. They used to lose 5% of their beans to defects. With HTsorter’s color sorter, losses dropped to 0.5%. That’s like saving 50 bags of coffee out of every 1,000—big money for small businesses!

Behind the Scenes: What Optical Sorting Machine Manufacturers Really Do

As one of the top optical sorting machine manufacturers, we don’t just sell boxes of tech. We solve real-world puzzles:

A nut farm needed to remove shell fragments without breaking good nuts. We tweaked the air pressure settings—problem solved.

A recycling startup struggled to sort black plastics (which most machines can’t “see”). We added special infrared sensors to our AI plastic sorting technology—now they recycle 90% of what they get.

We also train factory teams to use the machines and fix glitches fast. One customer joked, “It’s like having a tech genius on call 24/7… but cheaper!”

Newer models of best high tech color sorters do wild stuff:

Self-cleaning lenses: Dusty factory? No problem. The machine wipes its own “glasses” while working.

Wi-Fi alerts: Get a text if the machine spots a problem, like too many broken rice grains.

Energy saver mode: Uses less power than a hair dryer.

Whether you’re recycling plastic, packing snacks, or mining gems, best high tech color sorters are game-changers. At HTsorter, we’re proud to be optical sorting machine manufacturers that make tech simple, reliable, and eco-friendly.

What are the applications of color sorting machine

Color sorting machines are transforming industries by automating material separation based on color, shape, and composition. At HTsorter, we specialize in innovative solutions like AI-Powered Plastic Sorting Equipment, High-Speed Rice Color Sorters, and NIR Plastic Sorting Machines for PET/PVC, designed to meet diverse needs across sectors. Let’s explore how these technologies drive efficiency and sustainability.

AI-Powered Plastic Sorting Equipment: Revolutionizing Recycling

The global demand for sustainable practices has made plastic recycling a priority. Traditional methods struggle with mixed plastics, but AI-Powered Plastic Sorting Equipment uses deep learning to analyze material characteristics like color and texture in real time. This enables precise separation of PET, PVC, and other plastics—even without labels.

HTsorter’s AI systems adapt and improve over time, reducing waste and operational costs. These machines are vital in recycling plants, where they turn mixed waste into high-purity streams, boosting the value of recycled materials.

High-Speed Rice Color Sorter: Enhancing Food Safety

In agriculture, High-Speed Rice Color Sorters ensure premium quality by removing discolored or contaminated grains. Advanced CCD cameras and LED lighting detect defects at rapid speeds, while cloud-based analytics allow real-time adjustments for different rice varieties.

HTsorter’s rice sorters help mills meet strict food safety standards by eliminating mildew and foreign particles. Their compact, energy-efficient design suits both small farms and large processing facilities.

NIR Plastic Sorting Machine for PET/PVC: Precision in Material Recovery

Sorting PET and PVC is challenging, especially with black plastics. NIR Plastic Sorting Machines use near-infrared spectroscopy to identify materials by their chemical “fingerprints”.

HTsorter’s NIR systems achieve over 99% accuracy, crucial for producing food-grade recycled PET. Integrated dust removal and automatic calibration ensure reliability in high-volume environments like bottle recycling plants.

Why HTsorter?

We combine cutting-edge tech with practicality:

- Smart Connectivity: Cloud-based monitoring for seamless operations.

- Energy Efficiency: Low-power systems reduce costs.

- Global Support: 24/7 technical assistance.

Color sorting machines are essential for industries prioritizing quality and sustainability. With HTsorter’s AI-Powered Plastic Sorting Equipment, High-Speed Rice Color Sorters, and NIR Plastic Sorting Machines, businesses can achieve precision, efficiency, and eco-friendly outcomes. Discover how our solutions elevate your operations today.

Key Components of a High-Performance Aluminum Extrusion Machine

As a large aluminum extrusion machine 1