Generally, a large amount of sewage is produced in the production process of a stone factory. If it is not properly treated, it will not only cause environmental pollution, but also affect the actual production. Therefore, the stone sewage must be treated before it can be discharged and recycled. Stone sewage is produced by grinding, cutting, and polishing granite or slate in the stone processing process. Therefore, stone sewage contains a large amount of stone powder, residues and other substances, has high turbidity, and is difficult to process through natural precipitation. Therefore, precipitants, flocculants, etc. must be used to accelerate flocculation and sedimentation, so that impurities and suspended solids in the sewage can be clumped and precipitated, so as to achieve a clear effect. Currently, the comparative treatment found. Use polyacrylamide treatment effect. The stone processing plant collects the high turbidity sewage into the adjustment tank, and adds polyacrylamide precipitant in the adjustment tank. After being fully stirred and dissolved, it reacts with the fine suspended solids in the sewage, and the suspended solids pass through the polyacrylamide molecular framework to form flocs, which quickly settle to the bottom of the pool. Subsequently, the processed supernatant can be discharged and recycled. The mud and other sediments at the bottom of the pool can be backfilled after being dehydrated by a dehydrator or filter press without secondary pollution.

Application principle of polyacrylamide in stone wastewater treatment:

Stone processing industry wastewater generally adopts flocculation sedimentation method; the key to this method is the choice of flocculant—polyacrylamide. A good choice of polyacrylamide will accelerate the separation of mud and water. The sedimentation tank of the civil engineering part does not need to be so huge. Polyacrylamide is added to the sewage to promote a large number of difficult-to-precipitate fine particles produced during the process to agglomerate into large particles, which meet the standards for sewage purification in the stone industry, speed up their sedimentation, shorten the sewage treatment time and limit the reduction of suspended solids in the sewage The content and so on. And the treated water can be reused.

The advantages of polyacrylamide flocculant for wastewater treatment in stone processing plants:

1. The product has a variety of physical and chemical mechanisms and wide applicability, which is superior to the single limitation of traditional chemical water treatment agents.

2. Fast flocculation and sedimentation speed, dense sediment, low moisture content of sediment, and good dehydration. Low dosage and low operating cost.

3. Eliminate and degrade toxic substances, radioactive substances, metal compounds, and suspended solids in wastewater at one time, and clarify turbid water bodies.

The application principle of dehydrated polyacrylamide from waste stone cement slag:

The sludge settled in the wastewater treatment, and qualified enterprises choose mechanical dewatering. Most companies choose natural drying and manual cleaning. Stone sludge must be pretreated before mechanical dewatering, the purpose of which is to improve the dewatering performance of the sludge and increase the production capacity of dewatering equipment. Sewage plants usually use chemical conditioning methods to pre-treat the sludge, that is, by adding polyacrylamide to the sludge, the sludge particles are flocculated and the structure is strengthened to facilitate mechanical dewatering. The de-dried sludge is pulled away by the government-designated loading truck, and then pulled to a unified address for landfill, achieving the goal of environmental protection!

Special polyacrylamide for stone sewage treatment, the specific method of use is:

1. Dilute and dissolve the solid polyacrylamide medicament with water at a ratio of one-thousandth to three-thousandths.

2. Determine the amount of sewage treatment to be added according to the preliminary test, and then add the diluted polyacrylamide to the sewage in a fixed amount.

3. After sufficient stirring and reaction, it is then settled at rest.

Theory and practice have proved that anionic polyacrylamide is generally better, but the water quality of each case is very different. It is better to do a flocculation experiment in the laboratory for comparison.

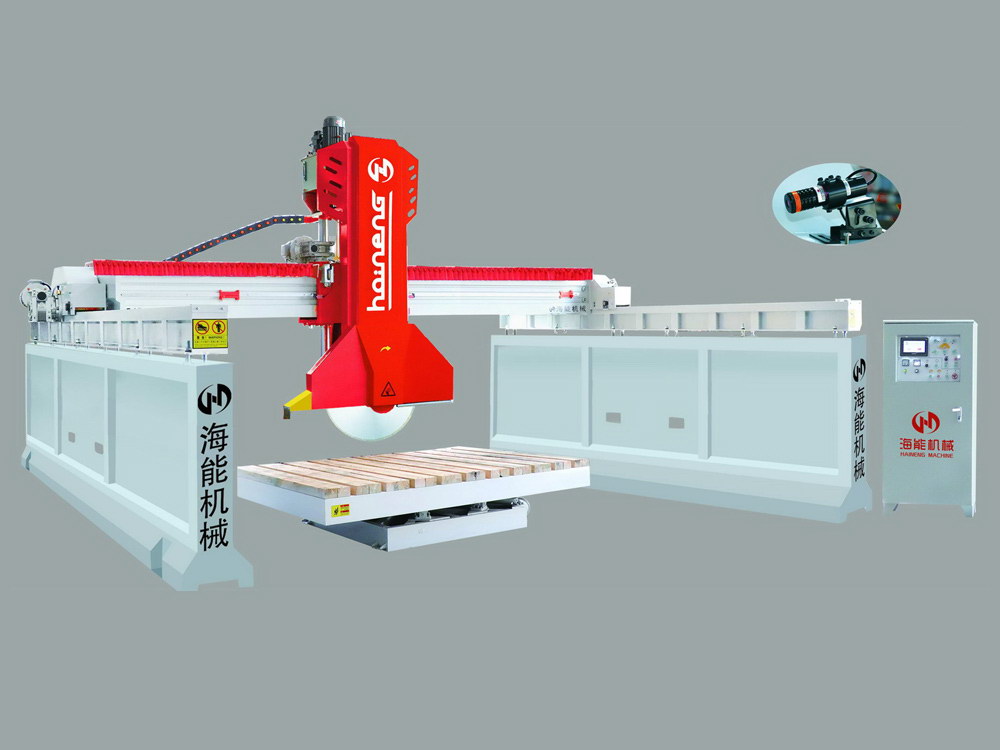

We are a professional Infrared stone cutting machine manufacturer, for more relevant information, and the latest quotation, click here to contact.