User selection environment test box must read

1、 Equipment selection criteria

There is currently no exact number of natural environmental factors and induced environmental factors that exist on the surface of the Earth and in the atmosphere, among which there are no less than a dozen factors that have a significant impact on the use and lifespan of engineering products (equipment). Engineers engaged in the study of environmental conditions for engineering products have compiled and summarized the environmental conditions that exist in nature and are induced by human activities into a series of testing standards and specifications to guide the environmental and reliability testing of engineering products. For example, GJB150- the National Military Standard of the People's Republic of China for Environmental Testing of Military Equipment, and GB2423- the National Standard of the People's Republic of China for Environmental Testing of Electrical and Electronic Products, which guides environmental testing of electrical and electronic products. Therefore, the main basis for selecting environmental and reliability testing equipment is the testing specifications and standards of engineering products.

Secondly, in order to standardize the tolerance of environmental testing conditions in experimental equipment and ensure the control accuracy of environmental parameters, national technical supervision agencies and various industrial departments have also formulated a series of calibration regulations for environmental testing equipment and detection instruments. Such as the national standard GB5170 of the People's Republic of China "Basic Parameter Calibration Method for Environmental Testing Equipment of Electrical and Electronic Products", and JJG190-89 "Trial Calibration Regulations for Electric Vibration Test Stand System" issued and implemented by the State Administration of Technical Supervision. These verification regulations are also an important basis for selecting environmental and reliability testing equipment. Testing equipment that does not meet the requirements of these verification regulations is not allowed to be put into use.

2、 Basic principles for equipment selection

The selection of environmental and reliability testing equipment should follow the following five basic principles:

1. Reproducibility of environmental conditions

It is impossible to fully and accurately reproduce the environmental conditions that exist in nature in the laboratory. However, within a certain tolerance range, people can accurately and approximately simulate the external environmental conditions that engineering products undergo during use, storage, transportation, and other processes. This passage can be summarized in engineering language as follows: "The environmental conditions (including platform environment) created by the testing equipment around the tested product should meet the requirements of the environmental conditions and their tolerances specified in the product testing specifications. The temperature box used for military product testing should not only meet the requirements of the national military standards GJB150.3-86 and GJB150.4-86 for different uniformity and temperature control accuracy. Only in this way can the reproducibility of environmental conditions be ensured in environmental testing.

2. Repeatability of environmental conditions

An environmental testing equipment may be used for multiple tests of the same type of product, and a tested engineering product may also be tested in different environmental testing equipment. In order to ensure the comparability of test results obtained for the same product under the same environmental testing conditions specified in the testing specifications, it is necessary to require the environmental conditions provided by the environmental testing equipment to be reproducible. This means that the stress levels (such as thermal stress, vibration stress, electrical stress, etc.) applied by environmental testing equipment to the tested product are consistent with the requirements of the same testing specification.

The repeatability of environmental conditions provided by environmental testing equipment is guaranteed by the national metrological verification department after passing the verification according to the verification regulations formulated by the national technical supervision agency. Therefore, it is necessary to require environmental testing equipment to meet the requirements of various technical indicators and accuracy indicators in the calibration regulations, and to not exceed the time limit specified in the calibration cycle in terms of usage time. If a very common electric vibration table is used, in addition to meeting technical indicators such as excitation force, frequency range, and load capacity, it must also meet the requirements of precision indicators such as lateral vibration ratio, table acceleration uniformity, and harmonic distortion specified in the calibration regulations. Moreover, the service life after each calibration is two years, and after two years, it must be re calibrated and qualified before being put into use.

3. Measurability of environmental condition parameters

The environmental conditions provided by any environmental testing equipment must be observable and controllable. This is not only to limit the environmental parameters within a certain tolerance range and ensure the reproducibility and repeatability of the test conditions, but also necessary for the safety of product testing, in order to prevent damage to the tested product caused by uncontrolled environmental conditions and unnecessary losses. At present, various experimental standards generally require that the accuracy of parameter testing should not be less than one-third of the allowable error under experimental conditions.

4. Exclusion of environmental testing conditions

Every time an environmental or reliability test is conducted, there are strict regulations on the category, magnitude, and tolerance of environmental factors, and non test required environmental factors are excluded from penetrating into it, in order to provide a definite basis for judging and analyzing product failure and fault modes during or after the test. Therefore, it is required that environmental testing equipment not only provide the specified environmental conditions, but also not allow any other environmental stress interference to be added to the tested product. As defined in the verification regulations for electric vibration tables, the table leakage magnetic flux, acceleration signal-to-noise ratio, and total root mean square value ratio of in band and out of band acceleration. The accuracy indicators such as random signal verification and harmonic distortion are all established as verification items to ensure the uniqueness of environmental testing conditions.

5. Safety and reliability of experimental equipment

Environmental testing, especially reliability testing, has a long testing cycle and sometimes targets high-value military products. During the testing process, testing personnel often need to operate, inspect or test around the site. Therefore, it is required that environmental testing equipment must have the characteristics of safe operation, convenient operation, reliable use, and long working life to ensure the normal progress of the testing itself. The various protection, alarm measures, and safety interlock devices of the testing equipment should be complete and reliable to ensure the safety and reliability of the testing personnel, the tested products, and the testing equipment itself.

3、 Selection of Temperature and Humidity Chamber

1. Selection of Capacity

When placing the test product (components, assemblies, parts or whole machine) into a climate chamber for testing, in order to ensure that the atmosphere around the test product can meet the environmental testing conditions specified in the test specifications, the working dimensions of the climate chamber and the overall dimensions of the test product should follow the following regulations:

a) The volume of the tested product (W × D × H) shall not exceed (20-35)% of the effective working space of the test chamber (20% is recommended). For products that generate heat during testing, it is recommended to use no more than 10%.

b) The ratio of the windward cross-sectional area of the tested product to the total area of the test chamber on that section shall not exceed (35-50)% (35% is recommended).

c) The distance between the outer surface of the tested product and the wall of the test chamber should be kept at least 100-150mm (recommended 150mm).

The above three provisions are actually interdependent and unified. Taking a 1 cubic meter cube box as an example, an area ratio of 1: (0.35-0.5) is equivalent to a volume ratio of 1: (0.207-0.354). A distance of 100-150mm from the box wall is equivalent to a volume ratio of 1: (0.343-0.512).

In summary, the working chamber volume of the climate environment test chamber should be at least 3-5 times the external volume of the tested product. The reasons for making such regulations are as follows:

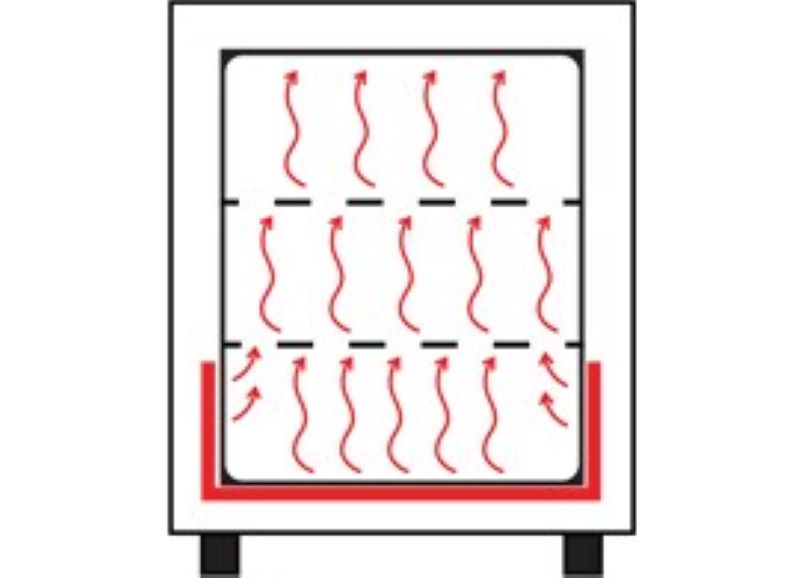

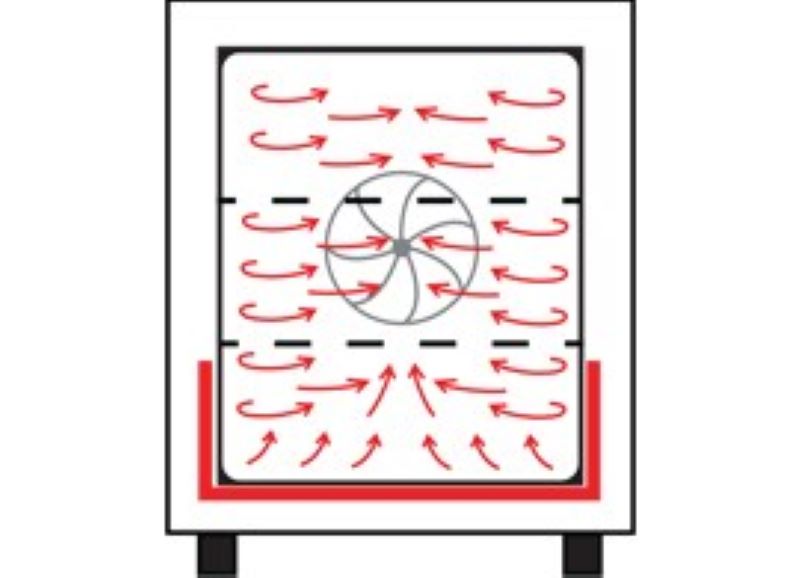

After the test piece is placed in the box, it occupies the smooth channel, and narrowing the channel will lead to an increase in airflow velocity. Accelerate the heat exchange between the airflow and the test piece. This is inconsistent with the reproduction of environmental conditions, as relevant standards stipulate that the air flow velocity around the test specimen in the test chamber should not exceed 1.7m/s for temperature environmental tests, in order to prevent the test specimen and the surrounding atmosphere from generating heat conduction that is not in line with reality. When unloaded, the average wind speed inside the test chamber is 0.6-0.8m/s, not exceeding 1m/s. When the space and area ratio specified in points a) and b) are met, the wind speed in the flow field may increase by (50-100)%, with an average maximum wind speed of (1-1.7) m/s. Meet the requirements specified in the standards. If the volume or windward cross-sectional area of the test piece is increased without restrictions during the experiment, the actual airflow speed during the test will exceed the maximum wind speed specified in the test standard, and the validity of the test results will be questioned.

The accuracy indicators of environmental parameters in the working chamber of the climate chamber, such as temperature, humidity, salt spray settling rate, etc., are all measured under no-load conditions. Once the test piece is placed, it will have an impact on the uniformity of the environmental parameters in the working chamber of the test chamber. The larger the space occupied by the test piece, the more severe this impact will be. Experimental data shows that the temperature difference between the windward and leeward sides in the flow field can reach 3-8 ℃, and in severe cases, it can be as high as 10 ℃ or more. Therefore, it is necessary to meet the requirements of a] and b] as much as possible to ensure the uniformity of environmental parameters around the tested product.

According to the principle of heat conduction, the temperature of the airflow near the box wall is usually 2-3 ℃ different from the temperature at the center of the flow field, and may even reach 5 ℃ at the upper and lower limits of high and low temperatures. The temperature of the box wall differs from the temperature of the flow field near the box wall by 2-3 ℃ (depending on the structure and material of the box wall). The greater the difference between the test temperature and the external atmospheric environment, the greater the temperature difference. Therefore, the space within a distance of 100-150mm from the box wall is unusable.

2. Selection of temperature range

At present, the range of temperature test chambers abroad is generally -73 to+177 ℃, or -70 to+180 ℃. Most domestic manufacturers generally operate at -80 to+130 ℃, -60 to+130 ℃, -40 to+130 ℃, and there are also high temperatures up to 150 ℃. These temperature ranges can usually meet the temperature testing needs of the vast majority of military and civilian products in China. Unless there are special requirements, such as products installed near heat sources such as engines, the upper temperature limit should not be blindly increased. Because the higher the upper limit temperature, the greater the temperature difference between the inside and outside of the box, and the poorer the uniformity of the flow field inside the box. The smaller the available studio size. On the other hand, the higher the upper limit temperature value, the higher the heat resistance requirements for insulation materials (such as glass wool) in the interlayer of the box wall. The higher the requirement for the sealing of the box, the higher the production cost of the box.

3. Selection of humidity range

The humidity indicators given by domestic and foreign environmental test chambers are mostly 20-98% RH or 30-98% RH. If the humid heat test chamber does not have a dehumidification system, the humidity range is 60-98%. This type of test chamber can only perform high humidity tests, but its price is much lower. It is worth noting that the corresponding temperature range or minimum dew point temperature should be indicated after the humidity index. Because relative humidity is directly related to temperature, for the same absolute humidity, the higher the temperature, the lower the relative humidity. For example, if the absolute humidity is 5g/Kg (referring to 5g of water vapor in 1kg of dry air), when the temperature is 29 ℃, the relative humidity is 20% RH, and when the temperature is 6 ℃, the relative humidity is 90% RH. When the temperature drops below 4 ℃ and the relative humidity exceeds 100%, condensation will occur inside the box.

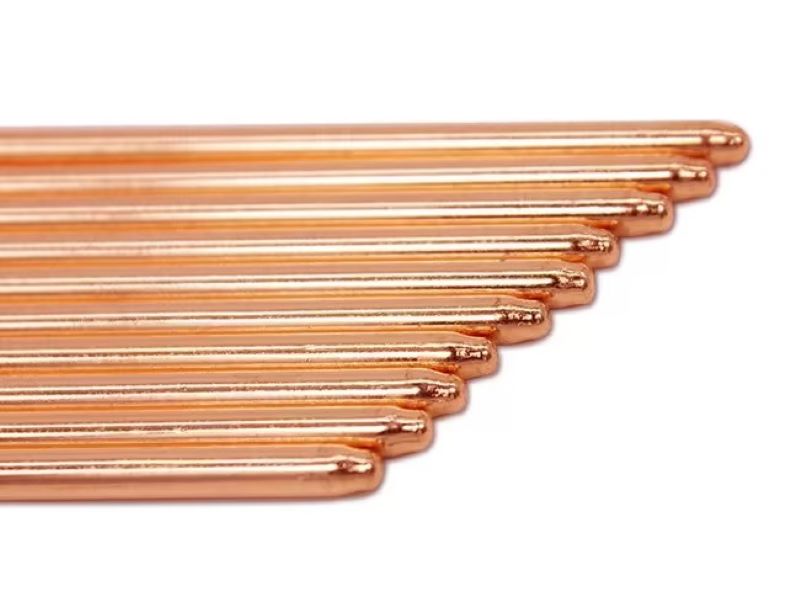

To achieve high temperature and high humidity, simply spray steam or atomized water droplets into the air of the box for humidification. Low temperature and humidity are relatively difficult to control because the absolute humidity at this time is very low, sometimes much lower than the absolute humidity in the atmosphere. It is necessary to dehumidify the air flowing inside the box to make it dry. At present, the vast majority of temperature and humidity chambers both domestically and internationally adopt the principle of refrigeration and dehumidification, which involves adding a set of refrigeration light pipes to the air conditioning room of the chamber. When humid air passes through a cold pipe, its relative humidity will reach 100% RH, as the air saturates and condenses on the light pipe, making the air drier. This dehumidification method theoretically can reach dew point temperatures below zero degrees, but when the surface temperature of the cold spot reaches 0 ℃, the water droplets condensed on the surface of the light pipe will freeze, affecting the heat exchange on the surface of the light pipe and reducing the dehumidification capacity. Also, because the box cannot be completely sealed, humid air from the atmosphere will seep into the box, causing the dew point temperature to rise. On the other hand, the moist air flowing between the light tubes only reaches saturation at the moment of contact with the light tubes (cold spots) and releases water vapor, so this dehumidification method is difficult to keep the dew point temperature inside the box below 0 ℃. The actual minimum dew point temperature achieved is 5-7 ℃. A dew point temperature of 5 ℃ is equivalent to an absolute moisture content of 0.0055g/Kg, corresponding to a relative humidity of 20% RH at a temperature of 30 ℃. If a temperature of 20 ℃ and a relative humidity of 20% RH are required, with a dew point temperature of -3 ℃, it is difficult to use refrigeration for dehumidification, and an air drying system must be selected to achieve it.

4. Selection of control mode

There are two types of temperature and humidity test chambers: constant test chamber and alternating test chamber.

The ordinary high and low temperature test chamber generally refers to a constant high and low temperature test chamber, which is controlled by setting a target temperature and has the ability to automatically maintain a constant temperature to the target temperature point. The control method of the constant temperature and humidity test chamber is also similar, setting a target temperature and humidity point, and the test chamber has the ability to automatically maintain a constant temperature to the target temperature and humidity point. The high and low temperature alternating test chamber has one or more programs for setting high and low temperature changes and cycles. The test chamber has the ability to complete the test process according to the preset curve, and can accurately control the heating and cooling rates within the maximum heating and cooling rate capability range, that is, the heating and cooling rates can be controlled according to the slope of the set curve. Similarly, the high and low temperature alternating humidity test chamber also has preset temperature and humidity curves, and the ability to control them according to the preset. Of course, alternating test chambers have the function of constant test chambers, but the manufacturing cost of alternating test chambers is relatively high because they need to be equipped with curve automatic recording devices, program controllers, and solve problems such as turning on the refrigeration machine when the temperature in the working room is high. Therefore, the price of alternating test chambers is generally more than 20% higher than that of constant test chambers. Therefore, we should take the need for experimental methods as the starting point and choose a constant test chamber or an alternating test chamber.

5. Selection of variable temperature rate

Ordinary high and low temperature test chambers do not have a cooling rate indicator, and the time from the ambient temperature to the nominal lowest temperature is generally 90-120 minutes. The high and low temperature alternating test chamber, as well as the high and low temperature alternating wet heat test chamber, both have temperature change speed requirements. The temperature change speed is generally required to be 1 ℃/min, and the speed can be adjusted within this speed range. The rapid temperature change test chamber has a fast temperature change rate, with heating and cooling rates ranging from 3 ℃/min to 15 ℃/min. In certain temperature ranges, the heating and cooling rates can even reach over 30 ℃/min.

The temperature range of various specifications and speeds of rapid temperature change test chambers is generally the same, that is, -60 to+130 ℃. However, the temperature range for assessing the cooling rate is not the same. According to different test requirements, the temperature range of rapid temperature change test chambers is -55 to+80 ℃, while others are -40 to+80 ℃.

There are two methods for determining the temperature change rate of the rapid temperature change test chamber: one is the average temperature rise and fall rate throughout the entire process, and the other is the linear temperature rise and fall rate (actually the average speed every 5 minutes). The average speed throughout the entire process refers to the ratio of the difference between the highest and lowest temperatures within the temperature range of the test chamber to the time. At present, the technical parameters of temperature change rate provided by various environmental testing equipment manufacturers abroad refer to the average rate throughout the entire process. The linear temperature rise and fall rate refers to the guaranteed temperature change rate within any 5-minute time period. In fact, for the rapid temperature change test chamber, the most difficult and critical stage to ensure the linear temperature rise and fall speed is the cooling rate that the test chamber can achieve during the last 5 minutes of the cooling period. From a certain perspective, the linear heating and cooling speed (average speed every 5 minutes) is more scientific. Therefore, it is best for the experimental equipment to have two parameters: the average temperature rise and fall speed throughout the entire process and the linear temperature rise and fall speed (average speed every 5 minutes). Generally speaking, the linear heating and cooling speed (average speed every 5 minutes) is half of the average heating and cooling speed throughout the entire process.

6. Wind speed

According to relevant standards, the wind speed inside the temperature and humidity chamber during environmental testing should be less than 1.7m/s. For the test itself, the lower the wind speed, the better. If the wind speed is too high, it will accelerate the heat exchange between the surface of the test piece and the airflow inside the chamber, which is not conducive to the authenticity of the test. But in order to ensure uniformity within the testing chamber, it is necessary to have circulating air inside the testing chamber. However, for rapid temperature change test chambers and comprehensive environmental test chambers with multiple factors such as temperature, humidity, and vibration, in order to pursue the rate of temperature change, it is necessary to accelerate the flow velocity of the circulating airflow inside the chamber, usually at a speed of 2-3m/s. Therefore, the wind speed limit varies for different usage purposes.

7. Temperature fluctuation

Temperature fluctuation is a relatively easy parameter to implement, and most test chambers produced by environmental testing equipment manufacturers can actually control temperature fluctuations within a range of ± 0.3 ℃.

8. Uniformity of temperature field

In order to simulate the actual environmental conditions that products experience in nature more accurately, it is necessary to ensure that the surrounding area of the tested product is under the same temperature environment conditions during environmental testing. Therefore, it is necessary to limit the temperature gradient and temperature fluctuation inside the test chamber. In the General Principles of Environmental Test Methods for Military Equipment (GJB150.1-86) of the National Military Standard, it is clearly stipulated that "the temperature of the measurement system near the test sample should be within ± 2 ℃ of the test temperature, and its temperature should not exceed 1 ℃/m or the total maximum value should be 2.2 ℃ (when the test sample is not working).

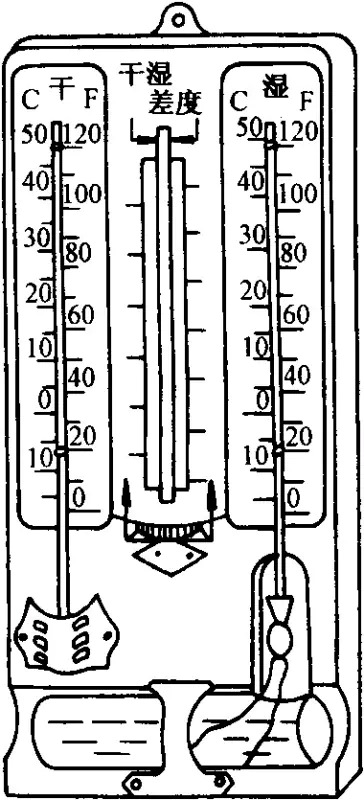

9. Precision control of humidity

The humidity measurement in the environmental testing chamber mostly adopts the dry wet bulb method. The manufacturing standard GB10586 for environmental testing equipment requires that the relative humidity deviation should be within ± 23% RH. To meet the requirements of humidity control accuracy, the temperature control accuracy of the humidity test chamber is relatively high, and the temperature fluctuation is generally less than ± 0.2 ℃. Otherwise, it will be difficult to meet the requirements for humidity control accuracy.

10. Cooling method selection

If the test chamber is equipped with a refrigeration system, the refrigeration system needs to be cooled. There are two forms of test chambers: air-cooled and water-cooled.

|

|

Forced air cooling |

Water-cooling |

|

Working conditions |

The equipment is easy to install, only need to power on. |

The ambient temperature should be lower than 28℃. If the ambient temperature is higher than 28℃, it has a certain impact on the refrigeration effect (preferably with air conditioning), the circulating cooling water system should be configured. |

|

Heat exchange effect |

Poor (relative to the water-cooling mode) |

Stable, good |

|

Noise |

Large (relative to the water-cooling mode) |

Less |

Objectively speaking, accelerated aging and outdoor aging have no convertibility, one is a variable, one is a fixed value, the only thing to do is to obtain a relative value, rather than an absolute value. Of course, it is not to say that relative values have no effect; on the contrary, relative values can also be very effective. For example, you will find that a slight change in design may double the durability of standard materials. Or you may find the same looking material from multiple suppliers, some of which age quickly, most of which take a moderate amount of time to age, and a smaller amount that ages after longer exposure. Or you may find that less expensive designs have the same durability against standard materials that have satisfactory performance over actual service life, such as 5 years.

Objectively speaking, accelerated aging and outdoor aging have no convertibility, one is a variable, one is a fixed value, the only thing to do is to obtain a relative value, rather than an absolute value. Of course, it is not to say that relative values have no effect; on the contrary, relative values can also be very effective. For example, you will find that a slight change in design may double the durability of standard materials. Or you may find the same looking material from multiple suppliers, some of which age quickly, most of which take a moderate amount of time to age, and a smaller amount that ages after longer exposure. Or you may find that less expensive designs have the same durability against standard materials that have satisfactory performance over actual service life, such as 5 years.