Vision counting machine helps you solve the problem of expensive labor

With the increasing of labor costs, many enterprises began to find ways to save labor costs.

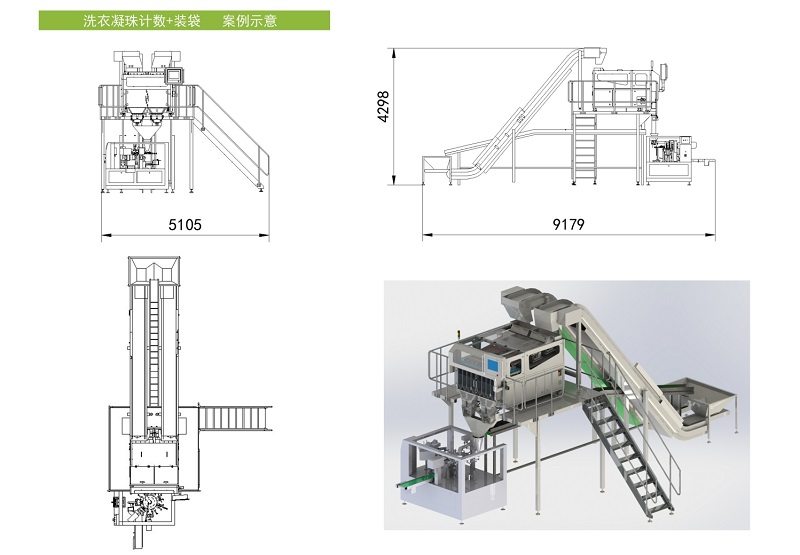

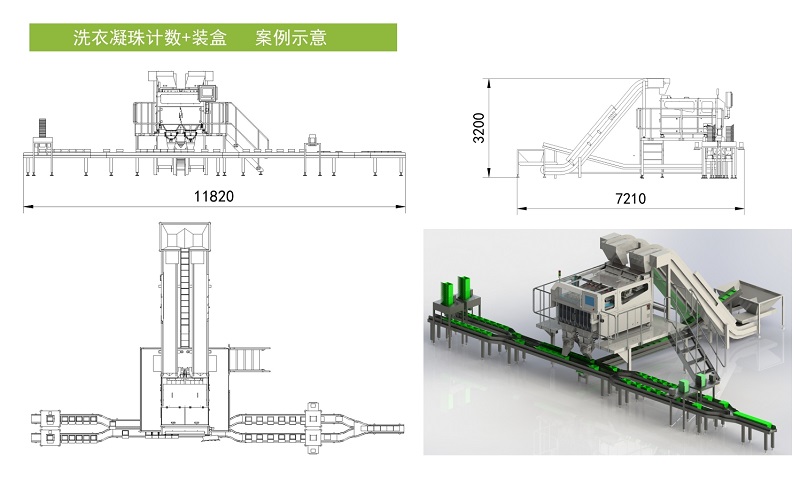

The customer said that they have 8-10 people in the counting and packaging process, and the packaging quality is also unstable. Therefore, they want to seek professional automatic vision counting machine that can reduce some labor for other links and improve packaging quality. Finally, after detailed demand docking, a customized vision counting machine was built based on the customer's packaging requirements, speed requirements and product characteristics.

The customer uses manual material collection and is equipped with a foot switch for discharging materials. If there are 30 pieces/package, the counting machine can reach 25 packages/minute.

If the speed requirement is fast and the budget is sufficient, an automatic packaging machine can be equipped with a signal docking with the counting machine to achieve full automation of counting and packaging.

We can do some calculations and see how the vision counting packaging machine can help you solve the problem of expensive labor.

Before customer use counting machine: according to the 8 people, packaging 2 people, the average one person can complete 2.5 packages a minute, then 8 people can complete 20 packages a minute. In 8 hours a day, 9600 packets a day.

After using our automatic vision counting packaging machine, according to the counting and packaging speed of 25 packages/minute, 2 people are required, one to load the finished product and the other to pack the finished product. To complete 9600 packages, it only takes 6.4 hours. The manual labor saves 6 people. If the salary is 60,000 RMB per year, the counting and packaging process can save 360,000 costs per year.

In addition, there are some hidden benefits:

1. If there is a shortage of quantity in manual packaging, it may cause customer complaints, affect the corporate image, and may lead to a reduction in order volume.

2. Since the vision counting machine will not be short of quantity, it can ensure packaging quality and customer satisfaction, and the corporate image is improved.