The difference between an electric tile cutter and a manual tile cutter comes down to how they operate and what types of tile jobs they’re best suited for. Here's a quick breakdown:

🔌 Electric Tile Cutter (Wet Saw)

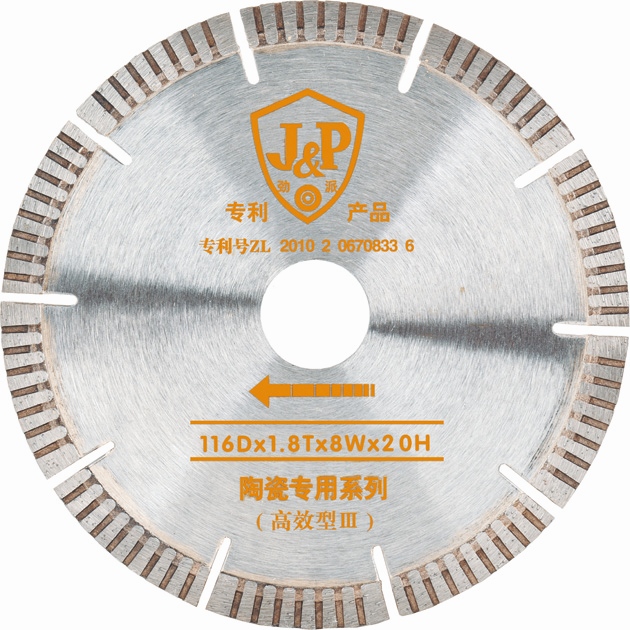

How it works: Uses a rotating diamond blade and water to cut through tile. The water cools the blade and reduces dust.

Pros:

-

Can cut through thicker and harder materials (like porcelain, marble, and stone).

-

Can make more precise cuts, including angled, curved, and notched cuts.

-

Better for large or complex tiling jobs.

Cons:

-

More expensive.

-

Bulky, requires power and water.

-

Messier to use.

-

Needs more setup and cleanup.

Best for:

Contractors or DIYers doing bigger or more intricate tile projects, or working with tough materials.

✂️ Manual Tile Cutter

How it works:You score the surface of the tile with a wheel and then snap it along the scored line.

Pros:

-

Inexpensive and portable.

-

Quick to set up and use.

-

Clean and quiet – no dust or noise.

Cons:

-

Limited to straight cuts.

-

Can struggle with thicker or harder tiles.

-

Less precise – might break tiles inconsistently if not careful.

Best for:

Smaller jobs with ceramic tiles and straight cuts.

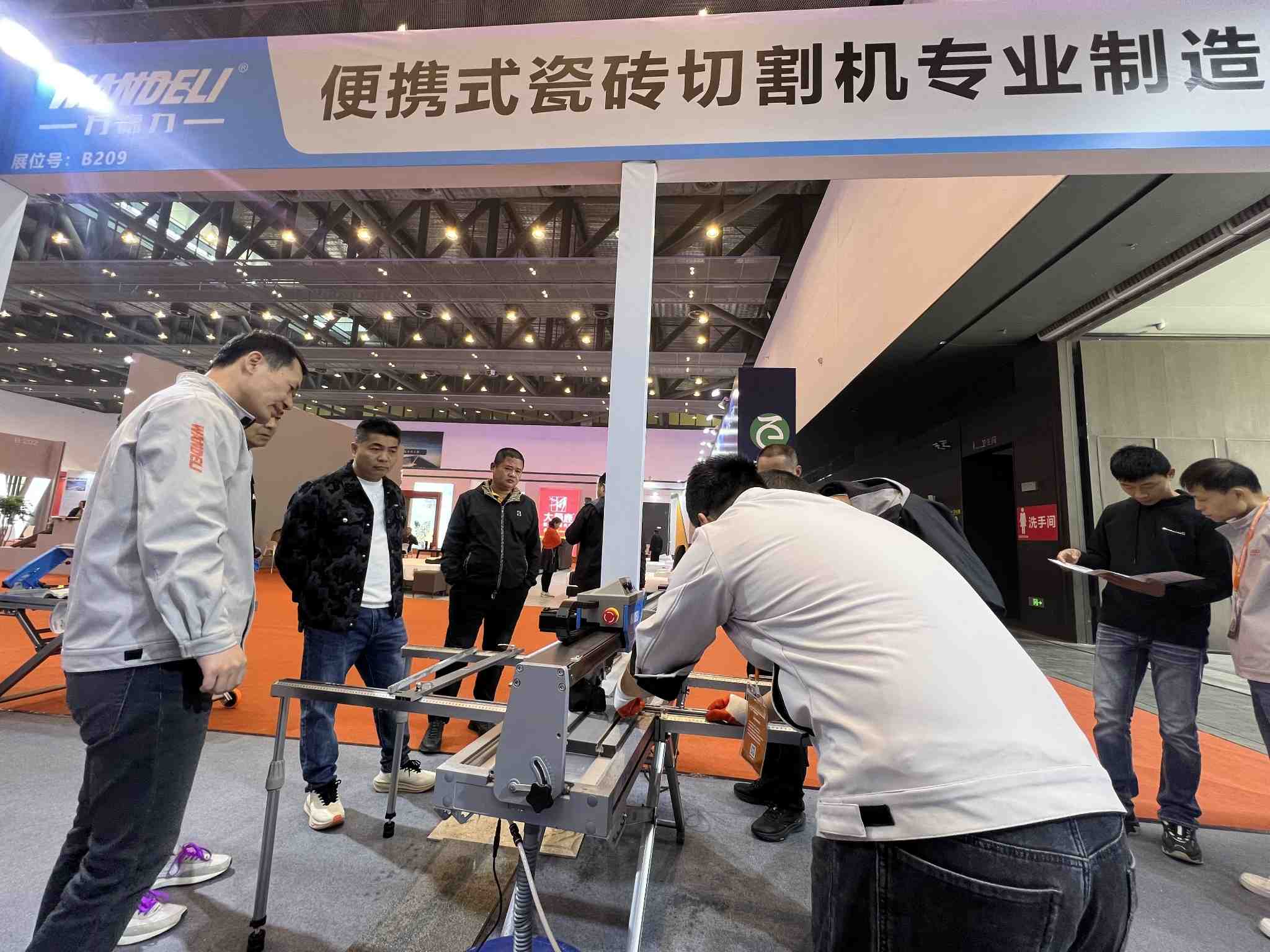

When choosing between a manual tile cutter and an electric tile cutter, it comes down to the complexity and scale of your project. Manual tile cutters are ideal for straight cuts on ceramic tiles—they’re affordable, portable, and easy to use. On the other hand, electric tile cutters, like the Wandeli QX-ZD-1200, are better suited for large-scale or professional tiling jobs. They can handle thicker tiles, make precise and angled cuts, and are compatible with a variety of materials including porcelain, marble, and stone.

The Wandeli QX-ZD-1200 stands out as a high-end electric tile cutter with a 1200mm cutting capacity, rail-guided system, integrated water cooling, and adjustable angle cuts, making it a top choice for precision, durability, and professional results.