Traditional environmental testing is based on the simulation of real environmental conditions, known as environmental simulation testing. This method is characterized by simulating real environments and incorporating design margins to ensure the product passes the test. However, its drawbacks include low efficiency and significant resource consumption.

Accelerated Environmental Testing (AET) is an emerging reliability testing technology. This approach breaks away from traditional reliability testing methods by introducing a stimulation mechanism, which significantly reduces testing time, improves efficiency, and lowers testing costs. The research and application of AET hold substantial practical significance for the advancement of reliability engineering.

Accelerated Environmental Testing

Stimulation testing involves applying stress and rapidly detecting environmental conditions to eliminate potential defects in products. The stresses applied in these tests do not simulate real environments but are instead aimed at maximizing stimulation efficiency.

Accelerated Environmental Testing is a form of stimulation testing that employs intensified stress conditions to assess product reliability. The level of acceleration in such tests is typically represented by an acceleration factor, defined as the ratio of a device's lifespan under natural operating conditions to its lifespan under accelerated conditions.

The stresses applied can include temperature, vibration, pressure, humidity (referred to as the "four comprehensive stresses"), and other factors. Combinations of these stresses are often more effective in certain scenarios. High-rate temperature cycling and broadband random vibration are recognized as the most effective forms of stimulation stress. There are two primary types of accelerated environmental testing: Accelerated Life Testing (ALT) and Reliability Enhancement Testing (RET).

Reliability Enhancement Testing (RET) is used to expose early failure faults related to product design and to determine the product's strength against random failures during its effective lifespan. Accelerated Life Testing aims to identify how, when, and why wear-out failures occur in products.

Below is a brief explanation of these two fundamental types.

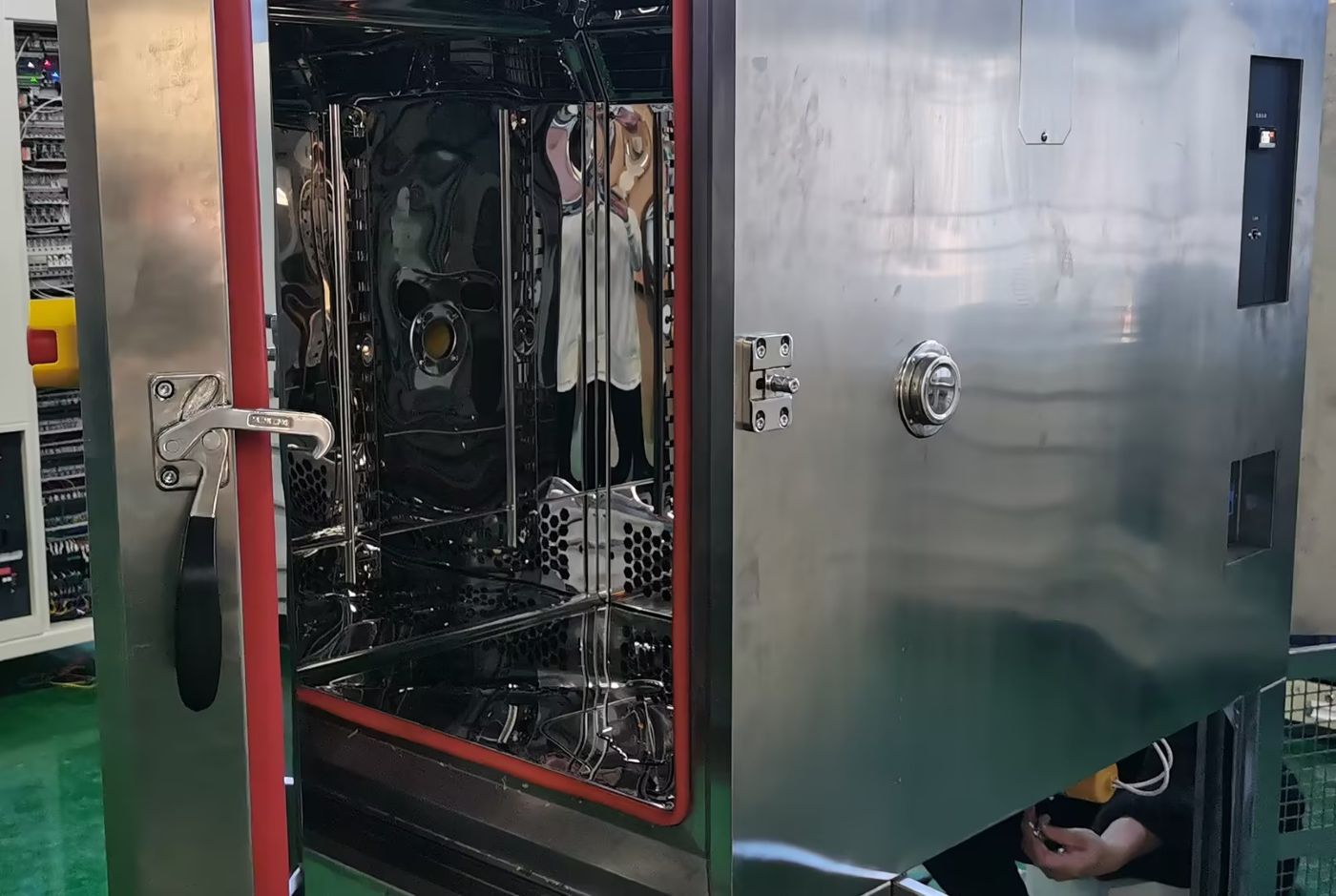

1. Accelerated Life Testing (ALT) : Environmental Test Chamber

Accelerated Life Testing is conducted on components, materials, and manufacturing processes to determine their lifespan. Its purpose is not to expose defects but to identify and quantify the failure mechanisms that lead to product wear-out at the end of its useful life. For products with long lifespans, ALT must be conducted over a sufficiently long period to estimate their lifespan accurately.

ALT is based on the assumption that the characteristics of a product under short-term, high-stress conditions are consistent with those under long-term, low-stress conditions. To shorten testing time, accelerated stresses are applied, a method known as Highly Accelerated Life Testing (HALT).

ALT provides valuable data on the expected wear mechanisms of products, which is crucial in today's market, where consumers increasingly demand information about the lifespan of the products they purchase. Estimating product lifespan is just one of the uses of ALT. It enables designers and manufacturers to gain a comprehensive understanding of the product, identify critical components, materials, and processes, and make necessary improvements and controls. Additionally, the data obtained from these tests instills confidence in both manufacturers and consumers.

ALT is typically performed on sampled products.

2. Reliability Enhancement Testing (RET)

Reliability Enhancement Testing goes by various names and forms, such as step-stress testing, stress life testing (STRIEF), and Highly Accelerated Life Testing (HALT). The goal of RET is to systematically apply increasing levels of environmental and operational stress to induce failures and expose design weaknesses, thereby evaluating the reliability of the product design. Therefore, RET should be implemented early in the product design and development cycle to facilitate design modifications.

Researchers in the field of reliability noted in the early 1980s that significant residual design defects offered considerable room for reliability improvement. Additionally, cost and development cycle time are critical factors in today's competitive market. Studies have shown that RET is one of the best methods to address these issues. It achieves higher reliability compared to traditional methods and, more importantly, provides early reliability insights in a short time, unlike traditional methods that require prolonged reliability growth (TAAF), thereby reducing costs.