Ⅰ. Proper Use of LABCOMPANION's Instrument

Environmental testing equipment remains a type of precision and high-value instrument. Correct operation and usage not only provide accurate data for testing personnel but also ensure long-term normal operation and extend the equipment's service life.

First, before conducting environmental tests, it is essential to familiarize oneself with the performance of the test samples, test conditions, procedures, and techniques. A thorough understanding of the technical specifications and structure of the testing equipment—particularly the operation and functionality of the controller—is crucial. Carefully reading the equipment’s operation manual can prevent malfunctions caused by operational errors, which may lead to sample damage or inaccurate test data.

Second, select the appropriate testing equipment. To ensure smooth test execution, suitable equipment should be chosen based on the characteristics of the test samples. A reasonable ratio should be maintained between the sample volume and the effective chamber capacity of the test chamber. For heat-dissipating samples, the volume should not exceed one-tenth of the chamber’s effective capacity. For non-heating samples, the volume should not exceed one-fifth. For example, a 21-inch color TV undergoing temperature storage testing may fit well in a 1-cubic-meter chamber, but a larger chamber is required when the TV is powered on due to heat generation.

Third, position the test samples correctly. Samples should be placed at least 10 cm away from the chamber walls. Multiple samples should be arranged on the same plane as much as possible. The placement should not obstruct the air outlet or inlet, and sufficient space should be left around the temperature and humidity sensors to ensure accurate readings.

Fourth, for tests requiring additional media, the correct type must be added according to specifications. For instance, water used in humidity test chambers must meet specific requirements: the resistivity should not be less than 500 Ω·m. Tap water typically has a resistivity of 10–100 Ω·m, distilled water 100–10,000 Ω·m, and deionized water 10,000–100,000 Ω·m. Therefore, distilled or deionized water must be used for humidity tests, and it should be fresh, as water exposed to air absorbs carbon dioxide and dust, reducing its resistivity over time. Purified water available on the market is a cost-effective and convenient alternative.

Fifth, proper use of humidity test chambers. The wet-bulb gauze or paper used in humidity chambers must meet specific standards—not just any gauze can substitute. Since relative humidity readings are derived from the dry-bulb and wet-bulb temperature difference (strictly speaking, also influenced by atmospheric pressure and airflow), the wet-bulb temperature depends on water absorption and evaporation rates, which are directly affected by the gauze quality. Meteorological standards require that wet-bulb gauze must be a specialized "wet-bulb gauze" made of linen. Incorrect gauze may lead to inaccurate humidity control. Additionally, the gauze must be installed properly: 100 mm in length, tightly wrapped around the sensor probe, with the probe positioned 25–30 mm above the water cup, and the gauze immersed in water to ensure precise humidity control.

Ⅱ. Maintenance of Environmental Testing Equipment

Environmental testing equipment comes in various types, but the most commonly used are high-temperature, low-temperature, and humidity chambers. Recently, combined temperature-humidity test chambers integrating these functions have become popular. These are more complex to repair and serve as representative examples. Below, we discuss the structure, common malfunctions, and troubleshooting methods for temperature-humidity test chambers.

(1) Structure of Common Temperature-Humidity Test Chambers

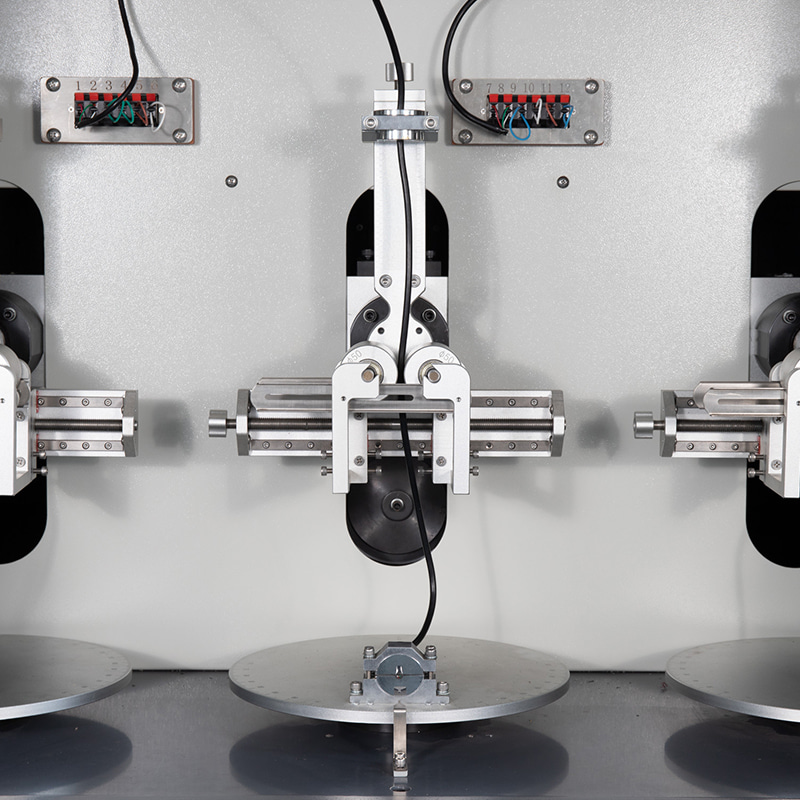

In addition to proper operation, test personnel should understand the equipment’s structure. A temperature-humidity test chamber consists of a chamber body, air circulation system, refrigeration system, heating system, and humidity control system. The air circulation system typically features adjustable airflow direction. The humidification system may use boiler-based or surface evaporation methods. The cooling and dehumidification system employs an air-conditioning refrigeration cycle. The heating system may use electric fin heaters or direct resistance wire heating. Temperature and humidity measurement methods include dry-wet bulb testing or direct humidity sensors. Control and display interfaces may feature separate or combined temperature-humidity controllers.

(2) Common Malfunctions and Troubleshooting Methods for Temperature-Humidity Test Chambers

1.High-Temperature Test Issues

- If the temperature fails to reach the set value, inspect the electrical system to identify faults.

- If the temperature rises too slowly, check the air circulation system, ensuring the damper is properly adjusted and the fan motor is functioning.

- If temperature overshooting occurs, recalibrate the PID settings.

- If the temperature spikes uncontrollably, the controller may be faulty and require replacement.

2.Low-Temperature Test Issues

- If the temperature drops too slowly or rebounds after reaching a certain point:

Ensure the chamber is pre-dried before testing.

Verify that samples are not overcrowded, obstructing airflow.

If these factors are ruled out, the refrigeration system may need professional servicing.

- Temperature rebound is often due to poor ambient conditions (e.g., insufficient clearance behind the chamber or high ambient temperature).

3.Humidity Test Issues

- If humidity reaches 100% or significantly deviates from the target:

For 100% humidity: Check if the wet-bulb gauze is dry. Inspect the water level in the wet-bulb sensor’s reservoir and the automatic water supply system. Replace or clean hardened gauze if necessary.

For low humidity: Verify the humidification system’s water supply and boiler level. If these are normal, the electrical control system may require professional repair.

4.Emergency Faults During Operation

- If the equipment malfunctions, the control panel will display an error code with an audible alarm. Operators can refer to the troubleshooting section in the manual to identify the issue and arrange for professional repairs to resume testing promptly.

Other environmental testing equipment may exhibit different issues, which should be analyzed and resolved case by case. Regular maintenance is essential, including cleaning the condenser, lubricating moving parts, and inspecting electrical controls. These measures are indispensable for ensuring equipment longevity and reliability.